Visia — AI-Powered Computer Vision for Industry

AI-powered quality, safety, and efficiency for modern factories

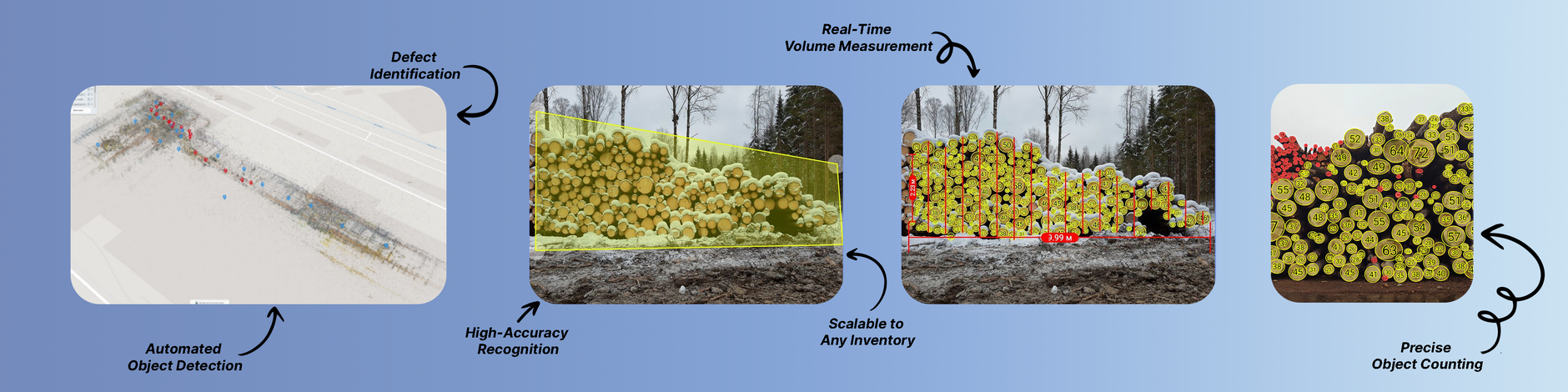

Visia is an AI-powered computer vision platform built to enhance quality assurance, safety, and operational efficiency in industrial environments.

From real-time defect detection to intelligent inventory management, it helps manufacturers reduce waste, minimize errors, and gain actionable insights for process optimization.

Our Contribution

A7 partnered with the client to design and deliver a computer vision system capable of running reliably on production lines:

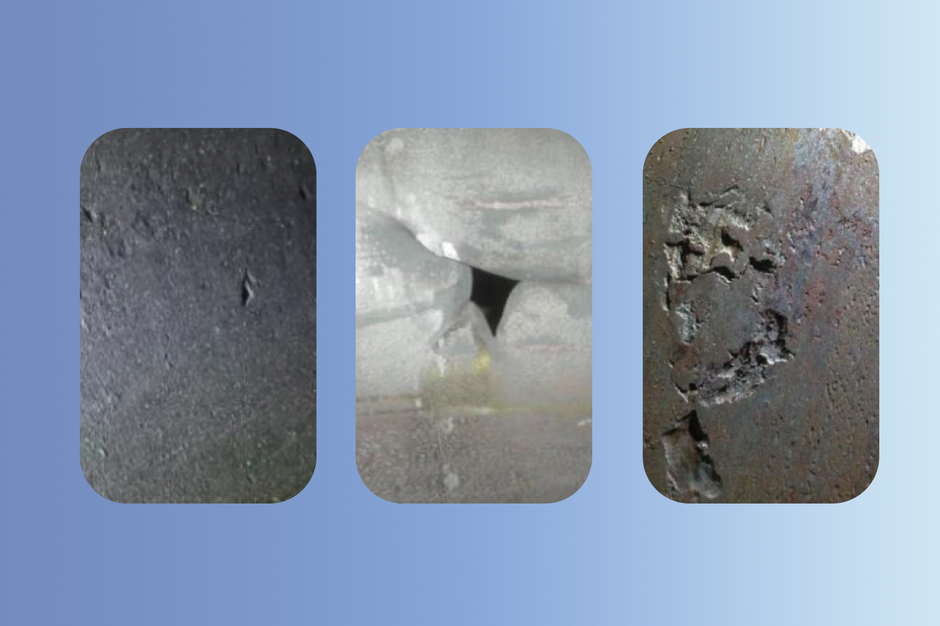

- Custom CV models designed and trained for defect detection on materials and finished products

- Scalable training pipelines to continuously improve models with evolving datasets

- Edge-ready deployment to ensure low latency and uninterrupted performance on the factory floor

- Integration with QA dashboards and reporting systems for seamless operator workflows

Results

The system achieved measurable improvements in efficiency and quality:

- 40% higher detection accuracy compared to manual inspection

- Lower inspection costs by reducing reliance on human operators

- Fewer errors and inconsistencies, improving product reliability

- Predictive insights enabling earlier intervention in upstream processes

Steps to Realize the Project

- Discovery & Data Collection

Captured production imagery, studied inspection workflows, and built datasets aligned with real factory conditions. - Model Design & Training

Developed tailored CV models using transfer learning and active dataset expansion for continuous adaptability. - Edge & Cloud Integration

Optimized models for edge devices to run in real time, while cloud pipelines enabled large-scale retraining. - Real-Time Monitoring Tools

Built dashboards and alerting systems for operators, including automated triggers to halt or reroute production. - Deployment & Continuous Learning

Established a feedback loop for ongoing retraining, ensuring the system adapts to new defect types and evolving production needs.