Ordestro — Modular ERP System

Smart ERP for scalable, transparent manufacturing

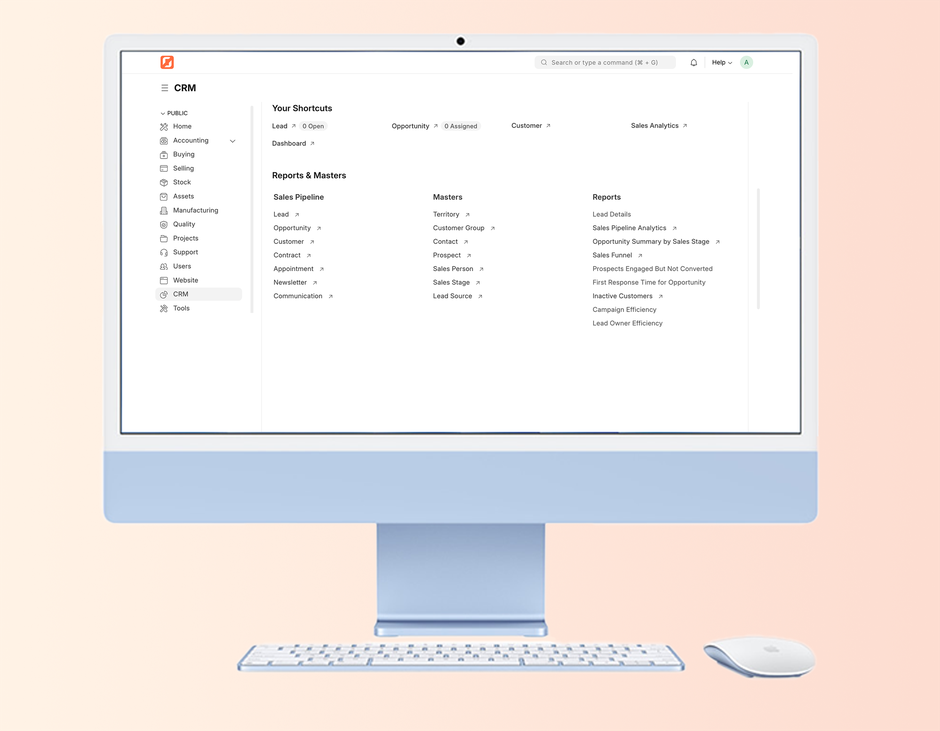

Ordestro is a modular ERP platform developed by A7 for industrial manufacturers.

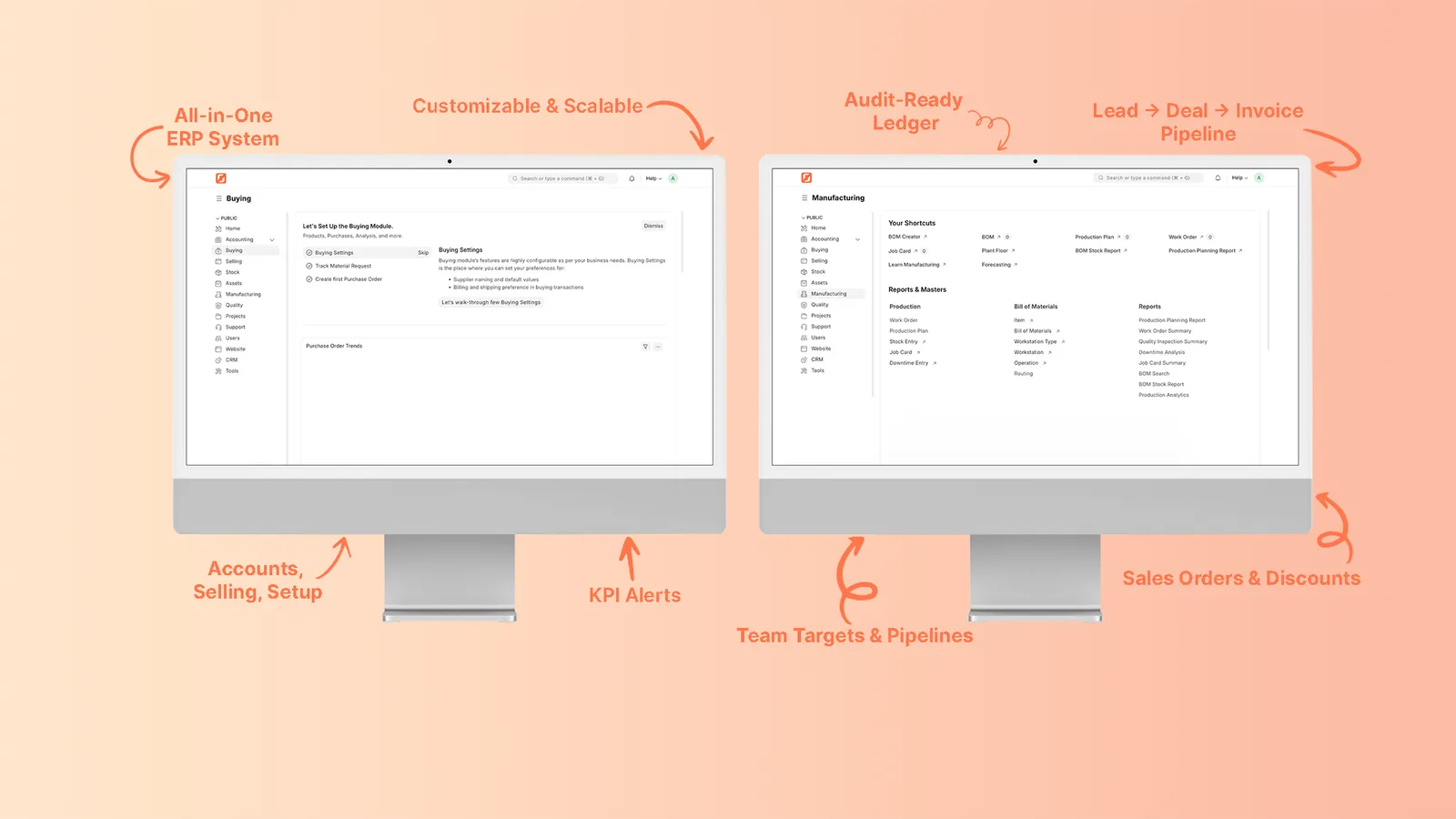

The system streamlines core operations — from inventory and procurement to production planning, workforce management, and reporting — enabling factories to achieve greater efficiency, transparency, and control across every stage of production.

Our Contribution

A7 managed the ERP project end-to-end, from requirements analysis through to rollout. The platform included:

- Inventory & procurement modules improving supply chain visibility

- Production planning & workforce management to optimize scheduling and resource allocation

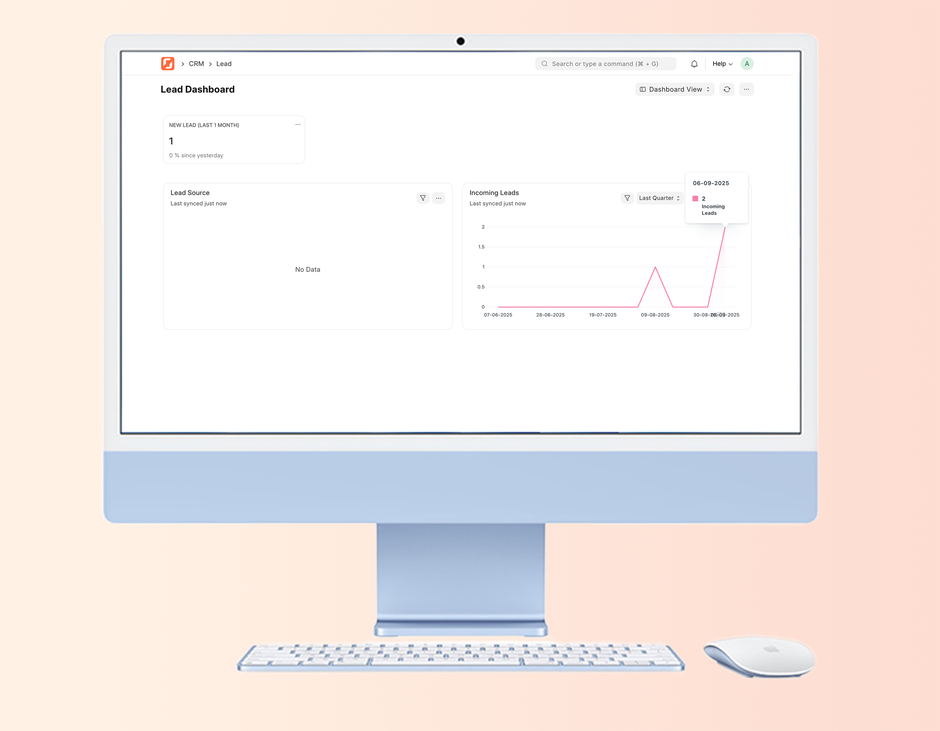

- Reporting & dashboards providing real-time insights into operational performance

- Scalable modular architecture enabling gradual rollout and future customization

Results

The ERP platform delivered measurable business value by helping the client:

- Reduce inefficiencies through automation of manual processes

- Gain real-time visibility into production cycles and factory operations

- Scale operations with a flexible system built for multi-site environments

Steps to Realize the Project

- Discovery & Factory Process Analysis

Our team conducted on-site audits, interviewed managers, and reviewed digital infrastructure to identify bottlenecks and opportunities for automation. - ERP Architecture Design

We designed a flexible, modular ERP tailored to the client’s workflows — covering inventory, planning, quality assurance, and reporting. Each module was developed independently for scalability and adaptability. - Implementation & Integration

The ERP was deployed with seamless integration into the client’s existing infrastructure, ensuring minimal disruption and fast adoption across the factory floor. - Dashboards & Reporting Tools

We built intuitive dashboards for operators and managers, allowing them to track performance, monitor production quality, and generate reports in real time. - Ongoing Support & Scaling

Post-deployment, we provided continuous support and extended the ERP across additional production lines. The modular design allowed the client to replicate and scale with minimal overhead.